MORE FREE TERM PAPERS MANAGEMENT:

|

||||||||||||||||||||||||||

ECONOMIC DRIVERS OF SUPPLY CHAIN CHOICES

Logistics management is concerned with the effective movement of goods

from point of production to point of consumption and managing the associated

services. Two aspects of such movement are noteworthy when non-bulk goods

are moved over long distances: first, goods are generally containerised,

and this is especially true for higher value goods. Second, the movement

of goods in such cases usually involves more than one major mode of transport.

Economic drivers

Economic hardship produced intense pressure to reduce costs across supply

chains. Unpredictable demand for goods and services, increased customer

demands, and volatile commodity .

Stainable supply chain management practice. The changes we are dealing

with today are not for a season. Some argue that continual economic and

social change is the “new normal. While the term “sustainable” has been

used lately in the context of environmental and green issues, it also

succinctly conveys the need to build and develop approaches and techniques

for managing and operating the supply chain.

We have identified five drivers that constitute the core of sustainable

practice in supply chain management. These drivers are optimization, synchronization,

profitability, adaptability and velocity.

1.optimization: it is the alignment of global supply

chain resources both tangible and intangible, owned or outsourced to facilitate

the success of supply chain members.

2.synchronization: it is the ability to coordinate, organize

and manage end-to-end supply chain flows — products, services, information

and financials.

3.profitability: it is the result of creating value through

supply chain activities. Asset performance, working capital and returns

on investment for infrastructure, technology and people are some of the

critical parts that create value in a global environment.

4.adaptability: it is the degree to which respective

supply chain members can change practices, processes and/or structures

of systems and networks in response to unexpected events, their effects

or impacts.

5.velocity: it is the speed at which end-to-end flows

occur in the supply chain. These five drivers of sustainable practice

should be a priority. It is an exercise that will help determine if your

supply chain can adapt and be successful in today’s “new normal” of continual

economic and social change.

Scale and scope of economic drivers

One of the characteristics which distinguishes network industries is the

presence of substantial economies of scale and scope. Economies of scale

alone have more of an impact on market structure than on market in the

case of a single-product natural monopoly, there will normally be a single

producer. However, in certain circumstances sufficient substitution in

consumption might exist between fixed and mobile end user network access.

In this case, the existence of economies of scale in a single production

process. Would not, itself, be determinative of market structure.

Supply chain

A supply chain is a system of organizations, people, technology, activities,

information and resources involved in moving a product or service from

supplier to customer. Supply chain activities transform natural resources,

raw materials and components into a finished product that is delivered

to the end customer.

Supply chain modelling

There are a variety of supply chain models, which address both the upstream

and downstream sides. The supply chain operations reference model, developed

by the supply chain council, measures total supply chain performance.

It is a process reference model for supply-chain management, spanning

from the supplier's supplier to the customer's customer. It includes delivery

and order fulfillment performance, production flexibility, warranty and

returns processing costs, inventory and asset turns, and other factors

in evaluating the overall effective performance of a supply chain.

The global supply chain forum introduced another supply chain model.while

each process will interface with key customers and suppliers, the customer

relationship management and supplier relationship management processes

form the critical linkages in the supply chain.

The american productivity & quality center process classification

framework sm is a high-level, industry-neutral enterprise process model

that allows organizations to see their business processes from a cross-industry

viewpoint.

Supply chain management

A supply chain is a network of facilities and distribution options that

performs the functions of procurement of materials, transformation of

these materials into intermediate and finished products, and the distribution

of these finished products to customers. Supply chains exist in both service

and manufacturing organizations, although the complexity of the chain

may vary greatly from industry to industry and firm to firm.

Supply chain management is the combination of art and science that goes

into improving the way your company finds the raw components it needs

to make a product or service and deliver it to customers. The following

are five basic components of supply chain manqgement.

1. Plan—this is the strategic portion of supply chain

managment(scm). Companies need a strategy for managing all the resources

that go toward meeting customer demand for their product or service.

2. Source—next, companies must choose suppliers to deliver

the goods and services they need to create their product.

3. Make—this is the manufacturing step. Supply chain

managers schedule the activities necessary for production, testing, packaging

and preparation for delivery. This is the most metric-intensive portion

of the supply chain—one where companies are able to measure quality levels,

production output and worker productivity.

4. Deliver—this is the part that many scm insiders refer

to as logistics, where companies coordinate the receipt of orders from

customers, develop a network of warehouses, pick carriers to get products

to customers and set up an invoicing system to receive payments.

5. Return—this can be a problematic part of the supply

chain for many companies. Supply chain planners have to create a responsive

and flexible network for receiving defective and excess products back

from their customers and supporting customers who have problems with delivered

products..

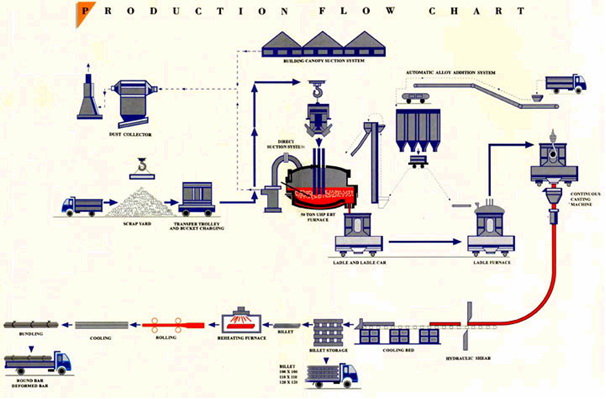

Production flow chart

Typical supply chain

Typical supply chain

The value of supply chain management

The value of supply chain management always starts with customers. They

want shorter times to market for new products, lower stock, obsolescence

and cash commitments and lower unit costs of purchasing and manufacturing.

At the same time, and with no compromise, they want increasing variety

and choice, wider distribution and increased customer and market responsiveness.

The value of supply chain management is that it can provide a pathway

to these seemingly contradictory goals. It can be descried as industrial

alchemy.

The typical benefits of an excellent supply chain

1. Reduction in total logistics costs as a percentage of revenue (material

acquisition, order management, inventory costs and finance/it support).

2. Reduction in order-fulfillment lead time.

3. Reduction in inventory.

4. Improvement in meeting commitment dates.

Supply chain decisions

There are four major decision areas in supply chain management:

1. Location,

2. Production,

3. Inventory, and

4. Transportation (distribution)

Advantage $ dis advantage of supply chain

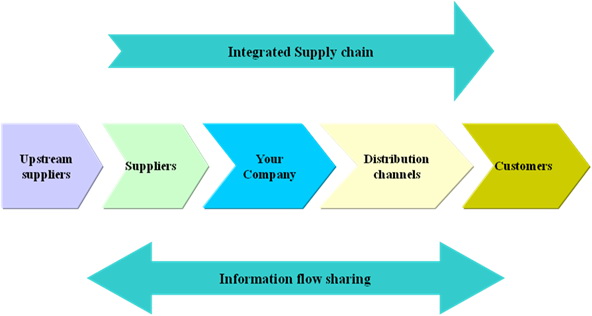

Advantages– an integrated supply chain gives greater

flexibility, ensures better control on the supply chain, thus making it

relatively easy to implement process or product innovations, minimise

the exposure to the risk of demand and price fluctuations, and facilitating

faster decision-making and implementation process.

Disadvantages– inaccessibility of cheaper feedstock in

market, and market dependence during the initial 3-4 years of feedstock

maturation.

References :

Arntzen, b. C., brown, g. G., harrison, t. P., & trafton, l. L. (1995). Global supply chain management at digital

Equipment corporation. Interfaces, 25(1), 69-93.Cohen, m. A., & agrawal, n. (1996). An empirical investigation of supplier management practices. In t. W. S.

Operations and information management department, university of pennsylvania (ed.) .Http://www.sls.wau.nl/mi/publications/index2.html

Http://biotech.iastate.edu/biotech_update/oct_97.html#low_sat.

Http://www.extension.umn.edu/distribution/businessmanagement/df7539.html

Http://money.cnn.com/magazines/fortune/fortune_archi.